Manufacturing Industries Are Saving Money & Streamlining Their Processes with AR & VR

Enhance training, quality control, workplace safety and maintenance with Augmented and Virtual Reality.

TRUSTED BY OVER 300 CLIENTS

THE NEXT UP AND COMING TECHNOLOGY

Numbers Don’t Lie AR & VR Are Transforming the Manufacturing Industry

Augmented Reality (AR) is ushering in a paradigm shift, transforming industries globally. Apple, Microsoft, and Google are all heavily investing resources in AR. Why? Because it’s the next frontier in technology.

Gravity Jack has been in this industry since 2009 and have been pioneers ever since.

$4.7B

AR & VR MANUFACTURING MARKET SIZE

MARKET AND MARKETS PRIVATE RESEARCH LTD

90%

FASTER TRAINING WITH AUGMENTED AND VIRTUAL REALITY

ACCORDING TO CAPEGEMINI

40%

OF COST IN MANUFACTURING CAN BE SAVED THROUGH AN AR OR VR EXPERIENCE

PWC DIGITAL IQ

Streamline Your Processes and Save Money at

Your Plant with Augmented and Virtual Reality

MANUFACTURING INDUSTRY REVOLUTIONIZED THROUGH EXTENDED RAELITY

Here Are Three Significant Ways AR & VR Help the Manufacturing Industries

Cost Reduction

AR & VR revolutionize manufacturing processes by reducing costs associated with prototyping and product design. Through virtual prototyping, companies can save on expenses related to physical models and materials, as well as minimize the need for costly iterations. Additionally, VR-powered remote collaboration tools streamline decision-making processes and cut down on travel expenses, resulting in substantial cost savings for manufacturing firms.

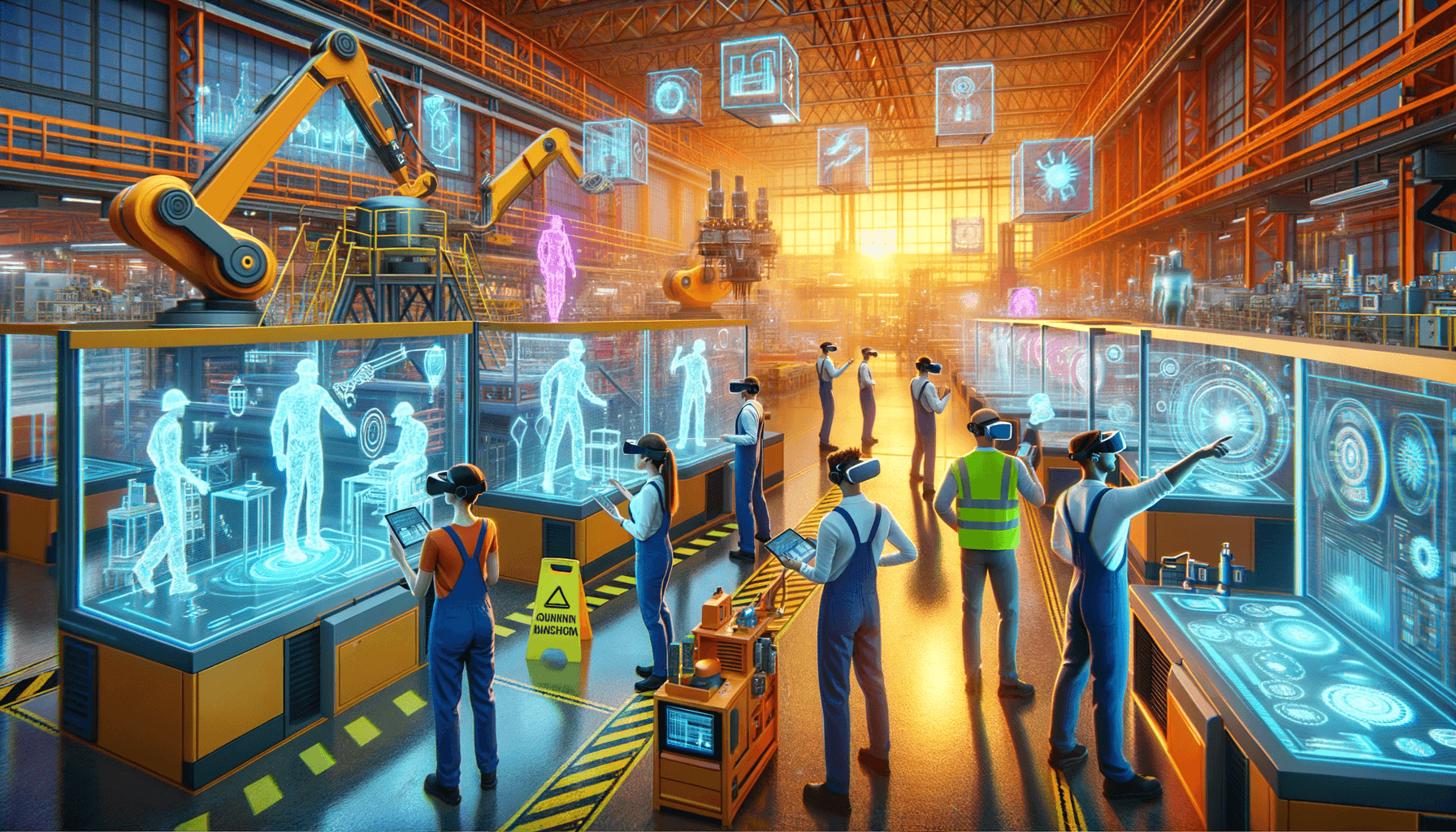

Optimize Training Processes & Enhance Workplace Safety

AR and VR technologies offer immersive training experiences, allowing employees to simulate real-world scenarios without risk. This hands-on approach enhances learning retention and comprehension, leading to more skilled and confident workers.

Quality Control

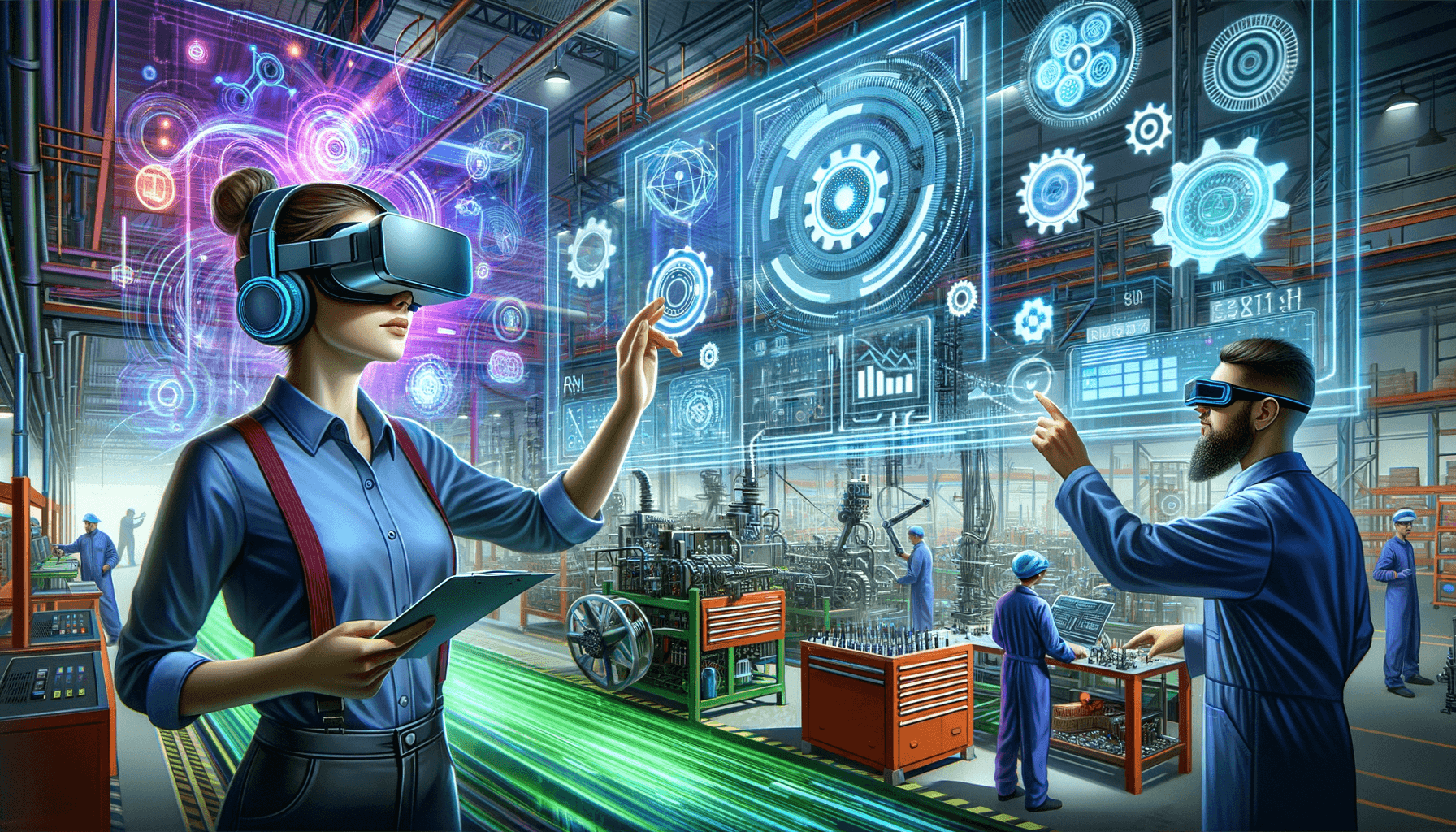

With AR-enabled inspections, workers can overlay digital information onto physical objects to identify defects and ensure compliance with quality standards. Moreover, VR simulations enable companies to assess and mitigate potential safety hazards within the manufacturing environment, reducing the risk of accidents or injuries.

Improved Performance On the Plant Floor Or Out on the Field and Inspect Machinery Like Never Before

Augmented Reality (AR) and Virtual Reality (VR) play pivotal roles in enhancing performance on the plant floor and streamlining machinery inspections. AR overlays real-time data and instructions onto physical equipment, empowering workers with crucial information at their fingertips. This reduces errors, improves efficiency, and accelerates tasks, ultimately boosting overall plant productivity. Moreover, VR enables immersive virtual inspections, allowing engineers to assess machinery remotely and identify potential issues before they escalate. By facilitating proactive maintenance and minimizing downtime, AR and VR technologies contribute to optimized plant operations and increased machinery reliability.

GRAVITY JACK CLIENT BLOG GALLERY

Augmented & Virtual Reality

for the Manufacturing Industry

What AR & VR Manufacturing Experiences Will Look Like in 2030

The Benefits of AR and VR Training in Manufacturing

Overcoming Challenges to Implementing AR and VR in Manufacturing

Transforming the Manufacturing Sales Process With AR & VR

Exploring the Impact of AR and VR on Worker Safety in Manufacturing

How AR and VR Are Reshaping the Manufacturing Industry

GRAVITY JACK MINI BLOGS

What AR & VR Manufacturing Experiences Will Look Like in 2030

Augmented Reality (AR) and Virtual Reality (VR) Technologies Transforming Manufacturing - A Glimpse into 2030

The manufacturing sector stands on the brink of a technological revolution that is set to deeply entrench augmented reality (AR) and virtual reality (VR) within its operations. Analysts predict a significant jump in market value, with AR and VR commanding a potential global market worth of $7.6 billion by 2030, according to ARtillery Intelligence. This growth heralds an era of transformation where productivity blends with innovation to redefine industry norms.

The Present Influence of AR and VR in Manufacturing

As we stand today, AR and VR are increasingly being adopted in the manufacturing space, enhancing various processes including design, training, and product development. Siemens, for instance, leverages AR to visualize the integration of new products into their current production lines. These technologies are no longer just possibilities; they're operational realities refining the way manufacturers design and create.

Anticipating the Future: AR and VR in 2030

By 2030, it is expected that the landscape of manufacturing will be reshaped by the exponential growth of AR and VR technologies. This prediction isn't unfounded—Statista reports suggest a stunning rise in AR/VR spending in the manufacturing sector to $19.8 billion, up from $1.5 billion in 2020. Innovations are poised to emerge from improvements in hardware, software, and integration capabilities, reimagining how we engage with the manufacturing process at every level.

Pioneering Immersive and Collaborative Tools in Manufacturing

As the geographical reach expands, especially in the rapidly industrializing Asia-Pacific region led by China, manufacturers will harness immersive tools to craft unparalleled work environments. Picture fully AR-powered workspaces where Ford's current VR ergonomic assessments become even more refined, significantly reducing physical strains for workers. Technologies like Microsoft's HoloLens will mature into sophisticated holographic displays, making remote collaboration more intuitive than ever, thereby slashing intervention times as seen with Thyssenkrupp.

Artificial Intelligence Meets AR and VR

One of the most profound integrations we're likely to witness is the combination of AR/VR with artificial intelligence (AI). This merger will herald advanced predictive maintenance capabilities, offering simulations that are not just immersive but intelligent. GE's current use of AR to digitally blueprint facilities will evolve, allowing for a seamless transition into even subtler predictive measures that will preempt machine failures with greater accuracy and foresight.

Leading Corporations Steering the AR and VR Surge

Leaders like Microsoft, Google, and PTC have begun staking their claims in the AR and VR playing field. Microsoft's HoloLens provides ground-breaking remote collaboration and training. Google's wearable Glass Enterprise Edition 2 amalgamates the physical and the digital for hands-free computing. And PTC's Vuforia AR enterprise solution paves the way for more efficient training and design processes.

The Far-Reaching Implications of AR and VR Evolution

Looking ahead, the implications of AR and VR in manufacturing will touch on three critical arenas: sustainability, efficiency, and personalization. The reduction in physical prototypes through AR and VR directly aligns with sustainable practices, lessening waste and ecological footprint. Efficiency will be boosted as error margins dwindle and physical travels for troubleshooting become a thing of the past. Lastly, the personalization capability will surge, transforming mass production into a more responsive, consumer-centric operation.

As we race toward 2030, we at Gravity Jack stand ready to be your partner in embracing these technologies. Our seasoned expertise in AR and VR development can facilitate the integration of these transformative tools into your manufacturing processes. Our involvement in creating dynamic AR experiences, such as "The Wartribe of Binyamin," showcases our commitment to pushing the boundaries of what AR and VR can achieve.

Stepping into a New Manufacturing Era with Gravity Jack

As the oldest AR company in the United States, we understand the strategic elements of AR and VR integration into modern implementations. With our diverse pricing models, expertly coded integrations, and creative ideation, we tailor our services to meet your specific needs, be it in marketing experiences, applications, training, education, or entertainment.

Join us in shaping the future of your manufacturing operations. Connect with our team at Gravity Jack to discuss how we can help advance your productivity and innovation to meet the thrilling opportunities of 2030 and beyond.

GRAVITY JACK MINI BLOGS

The Benefits of AR and VR Training in Manufacturing

Leveraging AR and VR for Effective Manufacturing Training

The manufacturing sector is undergoing a renaissance of training methodologies, propelled by the implementation of augmented reality (AR) and virtual reality (VR) technologies. These tools offer immersive experiences that can upgrade traditional training, ultimately enhancing workforce skills and operational efficiency. We at Gravity Jack have been at the forefront of this revolution, providing state-of-the-art AR and VR solutions tailored for the manufacturing industry's unique needs.

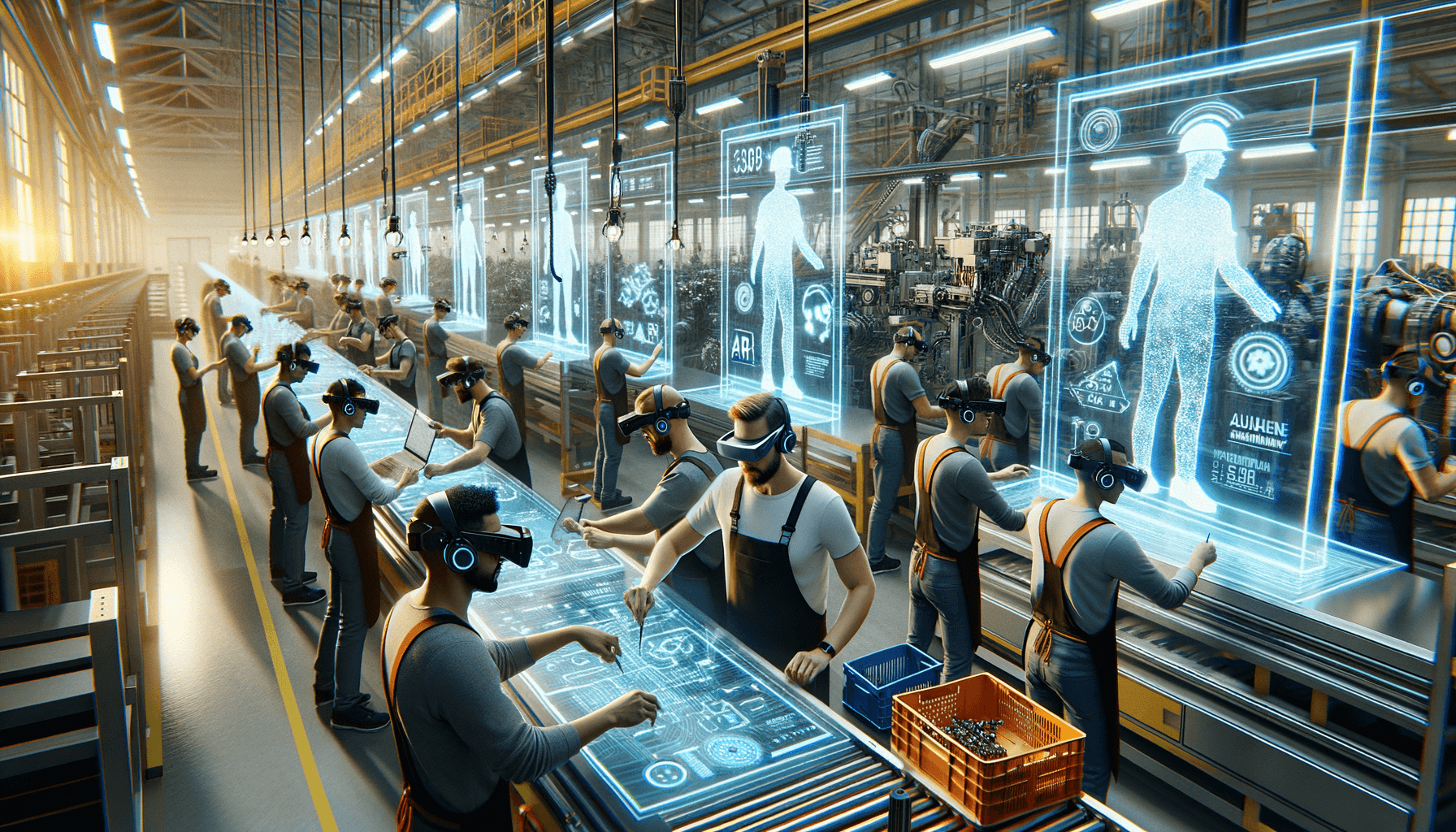

Transforming Training with Immersive Technologies

The use of AR and VR in training within the manufacturing sector is not just a trend but a strategic shift towards creating more effective and engaging learning experiences. These technologies enable trainers to simulate real-world scenarios in a virtual environment, where employees can practice and hone their skills without the constraints of the physical world. Learners can interact with 3D models of machinery, understand complex processes through virtual walkthroughs, and get a hands-on experience that previously would have involved substantial risks or resources. The utility of such immersive training is validated by the considerable cost and time savings reported by industry giants.

Case Studies Demonstrating Impact

Noteworthy success stories exemplify the shift towards immersive training. Lockheed Martin, for example, leveraged AR to enhance its technician training programs, seeing a marked decrease in the time required to comprehend training instructions and a reduction in costs. Boeing’s incorporation of AR into assembly training processes slashed assembly time and minimized errors. Mercedes-Benz’s employment of VR to simulate assembly for new production staff reduced their training time drastically while also increasing overall efficiency.

Economical and Efficient Learning

The reduction in training costs and time is a principal advantage of integrating AR and VR into manufacturing training. This is achieved by diminishing the need for physical resources, which are often expensive and not easily scalable. Moreover, the ability to repeat processes in a virtual space eliminates material waste and accelerates the learning curve. Our solutions at Gravity Jack are designed to maximize these efficiencies, contributing to a significant reduction in the overall training budget.

High Retention Rates through Engaging Experiences

When it comes to knowledge retention, interactive learning through AR and VR stands unparalleled with studies showing a staggering 75% retention rate for VR learners. The immersive nature of these technologies ensures that employees are not just passive receivers of information but active participants in the learning process. This engagement not only fosters a deeper understanding of the tasks at hand but also cultivates a more motivated workforce.

Flexibility for Diverse Learning Styles

Every individual has a unique learning style that traditional training methods may not cater to effectively. With AR and VR, we can customize training modules to accommodate these differences, making learning more inclusive and effective. Whether it's providing visually rich content for spatial learners or interactive scenarios for those who learn by doing, AR and VR technologies ensure that every employee has the ability to learn in the way that suits them best.

Pioneering the Future of Manufacturing Training

Our mission at Gravity Jack is to equip the manufacturing sector with cutting-edge AR and VR solutions that drive business success. We understand the intricate dynamics of this industry and strive to deliver training systems that not just meet but exceed our client's expectations. With a track record of successful implementations and a keen eye on market growth and emerging trends, we position ourselves as the go-to experts for your immersive technology needs.

To explore how Gravity Jack's AR and VR solutions can advance your manufacturing training, and to join the ranks of industry leaders who are redefining learning and efficiency, we invite you to get in touch with us. Together, we can explore the vast potential of AR and VR technologies to create a robust, skilled workforce that propels your company forward.

GRAVITY JACK MINI BLOGS

Overcoming Challenges to Implementing AR and VR in Manufacturing

Navigating the Integration of AR and VR in Manufacturing Operations

Manufacturing industries stand on the precipice of a technological revolution, with Augmented Reality (AR) and Virtual Reality (VR) poised to redefine operational processes. Yet, as we inch closer to embracing these technologies, it's important to acknowledge and understand the challenges they present. Within this landscape, our company, Gravity Jack, offers tailored solutions to facilitate a seamless transition into an augmented future.

The Financial Commitment of AR and VR

The integration of AR and VR technologies into manufacturing operations begins with a substantial financial investment. The infrastructure for AR and VR, including equipment, software, training, and integration, demands a significant capital outlay. However, this initial cost paves the way for long-term savings and efficiency gains. We at Gravity Jack understand these concerns and work closely with our clients to maximize their technology investment, ensuring that the solutions we provide are not only cutting-edge but also cost-effective.

Ensuring Compatibility with Legacy Systems

Compatibility with existing systems is a critical consideration for manufacturers when introducing AR and VR technologies. Often bound to aging infrastructure, companies seek seamless integration without the need to overhaul their entire operational framework. Here is where our expertise becomes invaluable. Our approach includes a systemic evaluation to identify the best pathways for integrating AR and VR technologies with existing systems, reducing potential friction and future-proofing technological investments.

Addressing Security and Privacy

Data security and privacy remain paramount within any technological adoption, especially for AR and VR, which harness sensitive information to function optimally. Acknowledging these concerns, our strategy encompasses the implementation of robust cybersecurity measures tailored to the unique needs of our manufacturing partners. This approach mitigates the risks associated with data integrity and maintains the trust and reliability that is essential within the manufacturing sector.

Partnering with Gravity Jack

To navigate these challenges successfully, a partnership with experienced AR and VR developers is crucial. Gravity Jack has a legacy of pioneering AR solutions and offers a wealth of expertise to assist manufacturing companies in this journey. Our comprehensive assessment of technology infrastructure and readiness ensures that the solutions we provide are not only compatible but also capable of bringing about transformational changes to operational processes.

Real-World Success Stories and Industry Innovators

In the realm of manufacturing, several industry leaders have already set benchmarks for AR and VR implementation. Boeing has notably harnessed AR to enhance the precision and efficiency of its technicians. FANUC has integrated VR into training modules to minimize downtime and boost productivity. Siemens leverages AR for remote troubleshooting, reducing travel requirements and accelerating problem resolution. These examples underscore the practical benefits and transformative impact that AR and VR can unleash in manufacturing operations.

Conclusion and Looking Ahead

The integration of AR and VR within the manufacturing sector is forecasted to continue its upward trajectory, led by companies eager to embrace these technologies' significant benefits. Coping with initial investment costs, ensuring system compatibility, and maintaining data security may pose initial challenges, but the opportunities for innovation and competitive advantage are immense. By drawing on our experience, companies can confidently transition into a digitally augmented era, characterized by enhanced efficiency and streamlined operations.

AR and VR represent more than just technological advancements; they are the keystones for driving a new era of manufacturing excellence.

Let us help you take the next step towards integrating AR and VR into your operations. With Gravity Jack, you gain a partner with the expertise to navigate the complexities of digital transformation. We invite you to explore our innovative solutions and consider how we can tailor our services to support your manufacturing goals.

Contact us today to discuss your AR and VR strategy, and let's build the manufacturing landscape of tomorrow, together.

GRAVITY JACK MINI BLOGS

Transforming the Manufacturing Sales Process With AR & VR

Transforming the Manufacturing Sales Process With AR & VR

AR and VR in Manufacturing: Growth and Opportunities

Augmented Reality (AR) and Virtual Reality (VR) are more than just buzzwords in the manufacturing sector. Statistics are showing an undeniable trend: the industrial AR market is projected to expand from $1.4 billion to $7.0 billion by 2025, signaling a remarkable annual growth rate of 38.1%. Similarly, the VR market in manufacturing is anticipated to reach $216 million in the upcoming year. Nearly one-third of US manufacturers have already integrated AR and VR into their operations, a figure that is predicted to climb as awareness of these technologies’ advantages continues to spread.

The Role of Industry Giants

Major players like Microsoft and Google are setting the stage for widespread implementation of AR and VR. Microsoft's HoloLens, for instance, plays a pivotal role in Lockheed Martin's engineering processes, aiding in spacecraft assembly with visual guidance. Google Glass, on the other hand, enhances efficiency on the factory floor at AGCO by providing workers with instant access to manuals and schematics as they work.

Case Studies: Boeing and Ford

Boeing’s implementation of AR through smart glasses that project wiring diagrams directly onto physical wires has cut their wiring time by a robust 25% and increased productivity by an impressive 40%. Meanwhile, Ford's utilization of VR in their Immersive Vehicle Environment lab allows engineers to evaluate vehicular designs and ergonomics much earlier in the production cycle, reducing the need for physical prototypes and fostering a culture of innovation.

Leveraging AR and VR for Enhanced Sales Strategies

The application of AR and VR in sales within the manufacturing industry is witnessing an upsurge. Effective sales strategies now encompass immersive product demonstrations with AR that showcase a product’s best features in an interactive and engaging manner. VR takes this a step further by creating virtual showrooms and simulations that allow prospective clients to explore a manufacturing facility or visualize products within their own real-world contexts. Such AR and VR experiences offer a level of engagement traditional sales methods struggle to match.

Augmented Reality: An Immersive Sales Experience

What sets AR apart in the sales process is its ability to superimpose digital information on physical products. This feature is incredibly effective in interactive presentations, where it allows potential customers to see how a product functions in a live, dynamic environment. It's an interactive, immersive approach that personalizes the sales pitch, giving each customer a tailored experience that taps into their specific needs and interests.

Virtual Reality: Beyond the Bounds of Physical Space

Virtual Reality, by creating immersive digital environments, completely removes the constraints of physical space and time from the sales equation. VR showrooms and simulations grant customers a virtually hands-on experience with products in contexts that would otherwise be logistically impractical, if not impossible. Imagine clients exploring manufacturing facilities across the globe or interacting with life-size models of machinery from the comfort of their office — VR makes this not just possible, but also seamless and highly engaging.

How Gravity Jack Innovates in AR and VR

At Gravity Jack, we understand that the strategic integration of AR and VR technologies can revolutionize the traditional sales approach in the manufacturing industry. With our extensive experience, we are well-positioned to deliver immersive experiences that heighten customer engagement and drive sales:

- We create personalized AR product demonstrations that not only highlight key features but also provide an engaging storyline around products, infusing each demo with a memorable narrative.

- Our VR solutions craft captivating virtual showrooms and simulations, allowing clients to explore, interact with, and understand products in immersive settings that encourage deeper connections.

- The combination of our creative ideation, multilingual support, and integration with various platforms ensures a comprehensive, customizable service for each client.

In dedicating over a decade to AR and VR technology, Gravity Jack has not only followed the evolution of these mediums but has actively shaped it. Our diverse portfolio of successful augmented and virtual reality solutions speaks volumes—whether you're looking at internal operations or aiming to amplify your sales process with cutting-edge technology.

The Gravity Jack Difference

We tailor our AR and VR solutions to each client's unique needs, ensuring that every aspect of the project, from concept to execution, is handled with the expertise and attention to detail that has made us a pioneer in the industry. With projects ranging from 100 to 5000 hours, our team can address a broad spectrum of challenges and opportunities. Gravity Jack's work isn't just about the technology—it's about creating immersive, transformative experiences that drive real-world results.

Are you ready to explore how AR and VR can transform your manufacturing sales process? Connect with us to learn more about our services and how we can help you differentiate in a competitive market while driving customer engagement and sales.

GRAVITY JACK MINI BLOGS

Exploring the Impact of AR and VR on Worker Safety in Manufacturing

AR and VR in Safety Training: Sailing Towards a Safer Manufacturing Sector

Safety within the manufacturing sector is paramount, not only as a compliance requirement but as a core company value that protects and values every employee. Traditionally, safety training has been delivered through conventional means, but with the advent of Augmented Reality (AR) and Virtual Reality (VR), a revolution is underway. Through these innovative technologies, we are able to offer immersive training experiences that drastically improve safety standards and protocols.

The Emergence of AR and VR in Industrial Training

Market Growth and Adoption

Recent research points to an astonishing growth trajectory for AR and VR in safety training, with VR alone projected to become a $6.3 billion industry by 2022. This impressive statistic is bolstered by a compound annual growth rate (CAGR) of 45%, signaling a substantial industry shift towards these technologies. Companies like Boeing have already integrated VR into their safety training regimes, reporting a 40% increase in productivity alongside significant cuts in training time. Such results can't be ignored and serve as a beacon for others to follow.

Real-World Applications and Improvements

AR and VR's real-world applications have shown to not only enhance employee preparedness for emergencies but also streamline the mundane aspects of safety training. For example, Honeywell's integration of intelligent wearables that combine AR and VR technology has proven vital. Similarly, Dassault Systèmes' 3D VR simulation platforms have demonstrated cost reductions and safety improvements. Manufacturing giants, including Ford and GE Aviation, also leverage these technologies to reduce risks associated with the operation of heavy machinery and complex systems.

Best Practices in AR/VR Safety Training

Exploring the effectiveness of AR and VR in safety protocols reveals that the most successful implementations are those that are customized and engaging. Siemens Healthineers' personalized VR simulations exemplify this approach effectively. DuPont Safety Resources demonstrates the power of gamification in AR safety training, a practice that has been shown to increase engagement and information retention among trainees. The underlying theme among industry leaders is the push for bespoke solutions that speak to the unique needs and challenges within their environments.

Driving Value Through Enhanced Safety Protocols

The application of AR and VR technology in safety training produces a multi-faceted impact:

- It enables workers to experience realistic scenarios without the associated risks.

- Training can be standardized across different locations, ensuring consistency in safety practices.

- It allows for the replication of rare or high-risk situations that would be impractical or dangerous to recreate physically.

These experiences, whether they're simulating emergency evacuations or the precise operation of heavy machinery, are invaluable in preparing employees for the complexities of real-world manufacturing environments.

Why Choose Our Company for Your AR and VR Training Needs

At the forefront of the AR and VR revolution, our company boasts the expertise and experience necessary to transform your safety training protocols. Our approach to integrating AR and VR into training is as nuanced as the technology itself. We offer:

- Customized Solutions: Tailored training modules designed specifically for your company's needs.

- Advanced Technology: Use of the latest AR and VR innovations to simulate even the most complex scenarios.

- Expertise and Support: A team of professionals providing constant support and insights throughout your safety training journey.

Our extensive portfolio speaks volumes about our capabilities and the trust industry leaders place in our services. Recognized as the oldest augmented reality company in the United States, we leverage our deep understanding of AR and VR to deliver unparalleled safety training solutions to the manufacturing sector.

In wrapping up, it is clear through numerous case studies and an explosion of market growth that AR and VR are more than just buzzwords—they are transformative tools in building a safer, more efficient manufacturing world.

Take the Next Step

If you are ready to elevate your manufacturing company's safety training through AR and VR, reach out to us. We're here to provide a seamless transition to a high-tech, high-safety standard. Visit our website, explore our services, and let's create a safer manufacturing environment together.

GRAVITY JACK MINI BLOGS

How AR and VR Are Reshaping the Manufacturing Industry

Revolutionary Role of AR & VR in Boosting Efficiency & Productivity in Manufacturing

In recent years, Augmented Reality (AR) and Virtual Reality (VR) technologies have become central to the evolution of various industries, particularly within manufacturing. These innovative tools facilitate intricate processes such as assembly guidance, maintenance, and quality control. The purpose of this blog is to delve into how companies are employing AR and VR to optimize operational flows, improve worker safety, and cultivate a culture of continuous innovation. We will explore a series of real-world cases and discuss the trajectory of AR and VR moving forward.

The Ascension of AR & VR in Modern Manufacturing

The advent of AR and VR in the manufacturing sector has led to a paradigm shift in how tasks are approached and executed. The figures speak for themselves—having begun with a market value of $1.1 billion in 2018, the AR & VR manufacturing sector is forecasted to escalate to $7 billion by 2023. This rapid growth is a clear testament to the vast potential and value these technologies offer to the industry. Moreover, a PWC report from 2021 highlights that nearly half of manufacturing companies are considering integrating AR and VR into their operations, a move indicative of a wider trend towards digital transformation in industrial environments.

Case Studies: Realizing Potential with AR and VR

Compelling success stories shed light on the tangible benefits of AR and VR. Aerospace giant Airbus experienced a significant improvement in their assembly processes, cutting down time by 30% and hitting a zero-error rate, thanks to the implementation of AR glasses. In the automotive space, the Ford Motor Company has revolutionized design processes using VR, leading to a decrease of up to 90% in their prototype production time. Lockheed Martin—an aerospace and defense stalwart—also reports striking enhancements, with a 46% increase in drilling speed and improved precision, attributed to AR tools.

These examples are indicative of the proficiency that our team at Gravity Jack brings to the table. With a strong emphasis on innovation and comprehensive understanding of AR and VR, we strive to replicate and even surpass such success stories by providing bespoke solutions tailored to the unique needs of our clients in manufacturing and beyond.

Enhancing Worker Safety with Immersive Technologies

AR and VR are not solely focused on productivity and efficiency—they also play an instrumental role in ensuring the safety and well-being of workers. Through realistic training simulations, these technologies allow employees to master complex tasks without any physical risk. Moreover, AR can offer real-time insights into machinery health, warning operators of any anomalies that could lead to potential hazards. Here, the proficiency of Gravity Jack in developing intuitive and impactful AR and VR applications shines through, as we aim to create safer work environments while simultaneously driving efficiency.

The Future Landscape: Trends and Prospects in AR and VR

Gazing into the future, the scope of AR and VR in manufacturing is only expanding. Remote assistance is on course to become commonplace, bridging the divide between experts and field workers across the globe. Moreover, the integration of AR and VR into working spaces is anticipated to revolutionize manufacturing floors, allowing for sophisticated simulations and monitoring that can vastly improve operational control and adaptability.

As forerunners in the domain of AR and VR technologies, our team takes pride in spearheading the development of applications and platforms that align with these future-forward trends. By leveraging our expertise, we aim to help businesses gain a competitive edge through the strategic use of AR and VR technologies.

Leading the Charge in AR & VR Solutions

Gravity Jack stands as a pioneer among technology providers, offering unmatched experience and skill in the realm of AR and VR as the oldest AR company in the United States. With a diverse portfolio of successful projects, we understand the intricacies of these technologies and how best to apply them for groundbreaking results in efficiency, productivity, and safety.

As an industry leader, we bring to the table: - Expertise garnered from years of experience in AR and VR. - Adaptable pricing and project timeframes tailored to the complexity and depth of integration. - Cutting-edge innovation, as showcased by our own AR game, "The Wartribe of Binyamin".

Discover the Gravity Jack Advantage

In a landscape teeming with possibilities, Gravity Jack provides the strategic insight and technological prowess necessary to harness the full potential of AR and VR. If your business is poised to explore the transformative capabilities of these incredible tools in manufacturing or any other sector, we invite you to discover what Gravity Jack can do for you.

Interested in learning how AR and VR can revolutionize your operations? Contact us to explore a partnership that takes your manufacturing capabilities into the next era of digital excellence.

WE LOVE CREATING EXPERIENCES THAT GENERATE REAL VALUE

Results Speak For Themselves

Brett Bawel

Program Manager at MindFuel

Working with the entire Gravity Jack team was an incredible experience. From the design and prototype stage, to the final delivery, the Gravity Jack team exceeded our expectations.

Jerry Paffendorf

CEO of Regrid

From the first exploratory conversation through project scoping and execution, the GJ team was great to work with at all levels… They took the time to listen, understand, and get excited about our unique business and AR opportunity. More than that, they executed beautifully.

HOW CAN WE MAKE THIS PROCESS EASIER FOR YOU?

Frequently Asked Questions

What are some examples of successful augmented reality implementations in manufacturing?

There are several ways AR can be integrated into the manufacturing sector, a few examples of note include using augmented reality for assembly guidance, where workers receive step-by-step visual instructions overlaid onto the physical components they are assembling. Gravity Jack specializes in developing customized AR solutions tailored to the client’s needs. These customizations can include but are not limited to creating intuitive AR interfaces that promote worker efficiency and accuracy on the assembly line. Additionally, we’ve helped companies deploy AR-based maintenance and repair guides, allowing technicians to access crucial information hands-free, reducing downtime, and improving overall productivity. With Gravity Jack’s expertise in AR development, we can design and implement solutions that optimize manufacturing processes and drive tangible business outcomes.

How can virtual reality be implemented in manufacturing?

VR is making huge strides in the manufacturing sector by offering immersive training simulations that replicate real-world scenarios, enabling employees to practice tasks in a safe and controlled environment. These training modules allow manufacturing personnel to familiarize themselves with complex machinery and procedures without risking safety or production disruptions. Additionally, VR facilitates collaborative design reviews, where stakeholders can interact with 3D models of products and factory layouts, leading to more informed decision-making and streamlined production processes. VR solutions for manufacturing also can extend to remote equipment operation training, enabling employees to gain hands-on experience with machinery from anywhere, reducing the need for costly travel, and minimizing downtime. With Gravity Jack’s expertise in VR development, we empower manufacturing companies to harness the full potential of virtual reality for training, design, and operational efficiency.

What are the barriers to entry for manufacturing leveraging AR & VR technology?

Integrating AR and VR solutions into existing manufacturing processes requires investment in hardware, software development, and employee training. However, our team at Gravity Jack works closely with clients to develop cost-effective solutions tailored to their specific needs and budget constraints. Additionally, concerns about compatibility with existing systems, data security, and privacy may pose challenges for some manufacturing companies. Gravity Jack addresses these concerns by providing comprehensive consultations and developing customized AR and VR solutions that seamlessly integrate with existing workflows while prioritizing data security and compliance.

Our process is unique to our company. How does Gravity Jack account for that?

We understand that each manufacturing company has unique processes, challenges, and goals. That’s why we take a personalized approach to every project, ensuring that our AR and VR solutions are tailored to meet your specific needs and requirements. Our team of experts collaborates closely with your company to gain a deep understanding of your operations, allowing us to develop custom AR and VR experiences that align perfectly with your business objectives. At Gravity Jack, we excel in creating custom 3D models and animations that accurately represent any machine or manufacturing process. Our team of experienced designers and developers has the expertise to recreate even the most complex machinery with precision and detail.

Can AR & VR be used in our team’s sales process?

Both AR and VR can significantly enhance the sales process in manufacturing by providing immersive product experiences, interactive demonstrations, and virtual showrooms. AR can be used to overlay digital information onto physical products, allowing sales representatives to showcase features, specifications, and customization options in real-time. This interactive experience helps potential buyers better understand the value proposition of your products and makes the sales process more engaging and memorable. VR, on the other hand, enables virtual product demonstrations and simulations, allowing customers to experience your products in a virtual environment. Whether it’s showcasing complex machinery in operation or giving clients a virtual tour of your manufacturing facilities, VR provides a powerful tool for visualizing products and conveying their benefits.