Augmented Reality: A Gateway to Comprehensive Product Knowledge for Manufacturing Workforce

Introduction

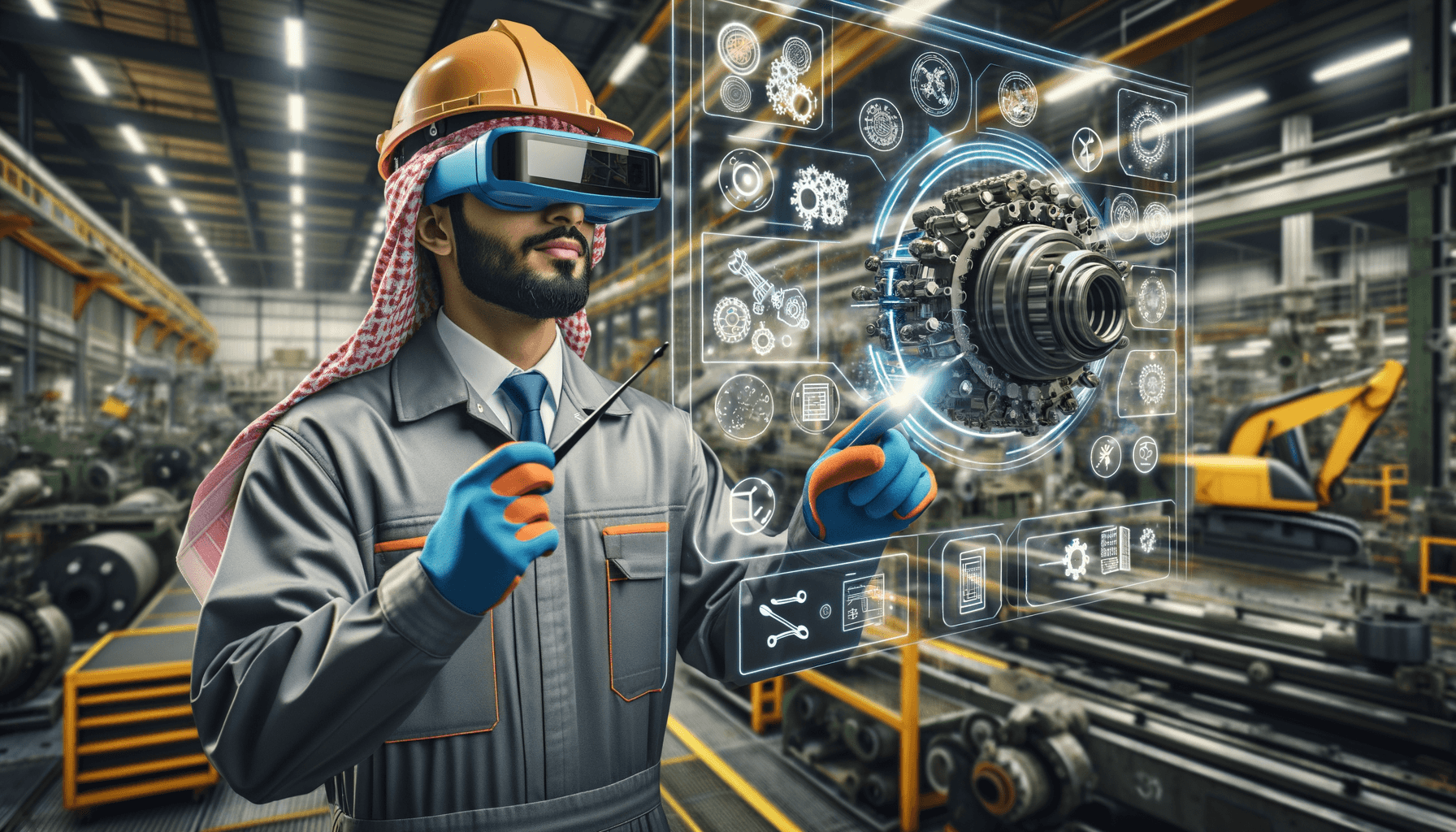

In today’s technology-driven manufacturing landscape, Augmented Reality (AR) has emerged as a crucial tool for employee education and training. As a pioneer in the AR space, Gravity Jack specializes in creating immersive AR training modules perfectly suited for the complexity and scale of manufacturing environments.

The Role and Impact of AR in Employee Training

Enhancing Product Knowledge

- Sophisticated Understanding: AR presents a unique opportunity for employees to gain an intricate comprehension of products.

- Visual Interaction: Staff can visualize and interact with product components and functionalities in real-time, fostering a deep grasp of intricate details.

Facilitating Hands-On Learning Experiences

- Virtual Interaction with Machinery: By simulating equipment, AR provides a risk-free zone for employees to learn maneuvers, lowering accident risks and furthering workplace safety.

Market Growth and Adoption Scale

The adoption of AR in manufacturing is rapidly increasing. A PwC report predicts a 24.1% CAGR by 2025. Global leaders like Ford and Boeing are leveraging AR to revolutionize their training approaches, indicating a significant shift in professional development norms.

Best Practices in the Industry

- Virtual Prototyping: This method streamlines the design process with cost-efficiency.

- Equipment Maintenance Inspection: Enhanced 3D visuals delivered by AR tools assist in precise inspection and maintenance.

- Expedited Knowledge Transfer: AR-generated digital twins of machinery allow for autonomous learning, enhancing knowledge retention.

Case Studies: Successful Implementations

- Gravity Jack: Crafted an AR application for complex mechanical systems that serve as a linchpin for comprehensive component understanding.

- Ford: Embraced AR via Microsoft HoloLens for design prototyping, optimizing their design efficacy.

- Boeing: Integrated AR in manufacturing to uplift efficiency, slash assembly times, and augment training outcomes.

Industry Leaders

Alongside Gravity Jack, companies like Bosch, Epson, Google, and Microsoft are spearheading the innovation in industrial AR applications, indicating a vibrant and forward-moving industry landscape.

Conclusion

The role of AR in manufacturing, particularly in enhancing employee product knowledge, is not only clear but is becoming a staple in the sector. Gravity Jack positions itself as an innovator within this realm, tailoring AR solutions to meet the nuanced demands of today’s manufacturing industry.

Consider exploring Gravity Jack’s AR training solutions to elevate your manufacturing operations. Please visit our website to learn more about how our AR expertise can enhance your workforce’s product knowledge and training experience.