What AR & VR Manufacturing Experiences Will Look Like in 2030

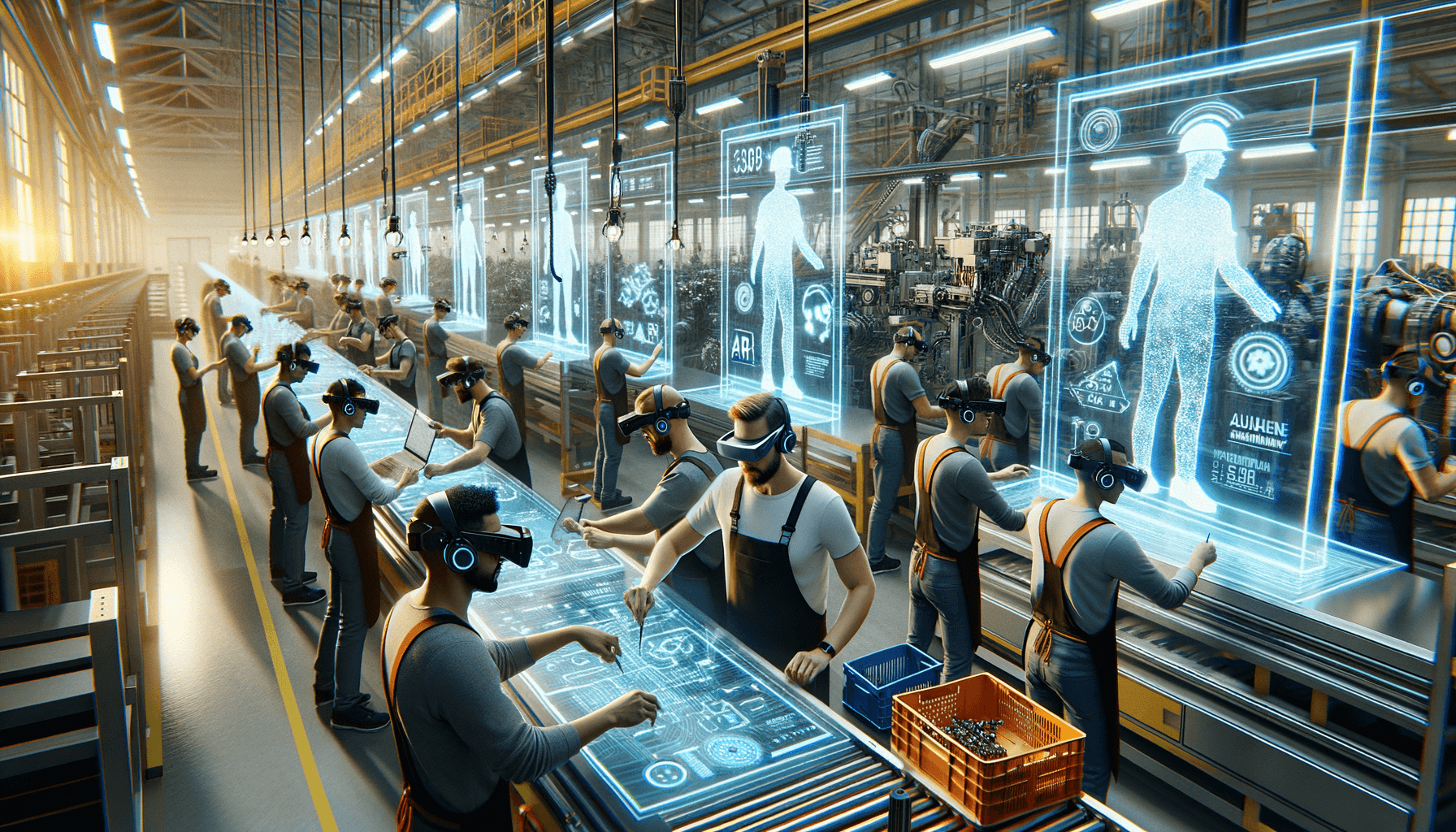

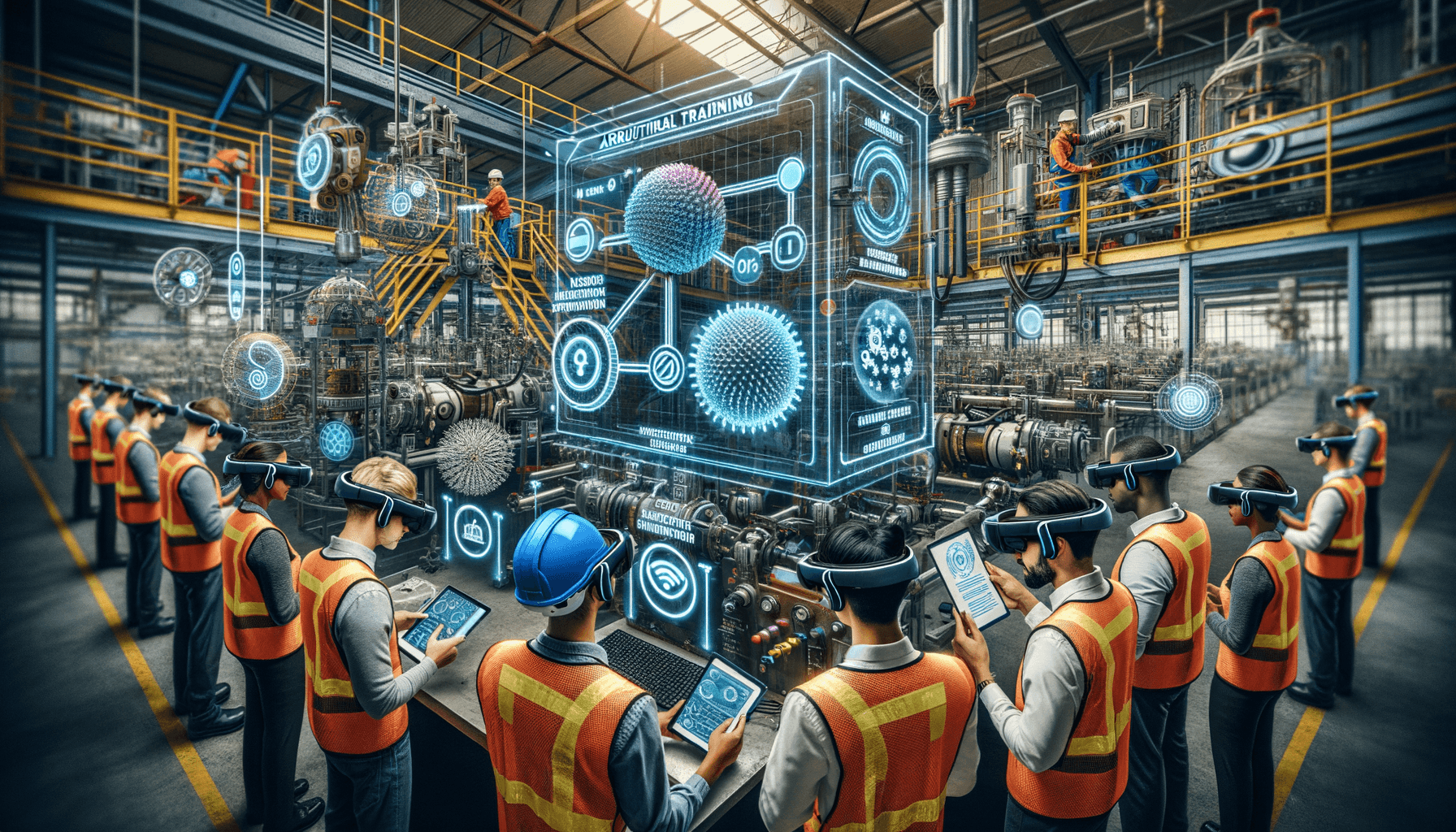

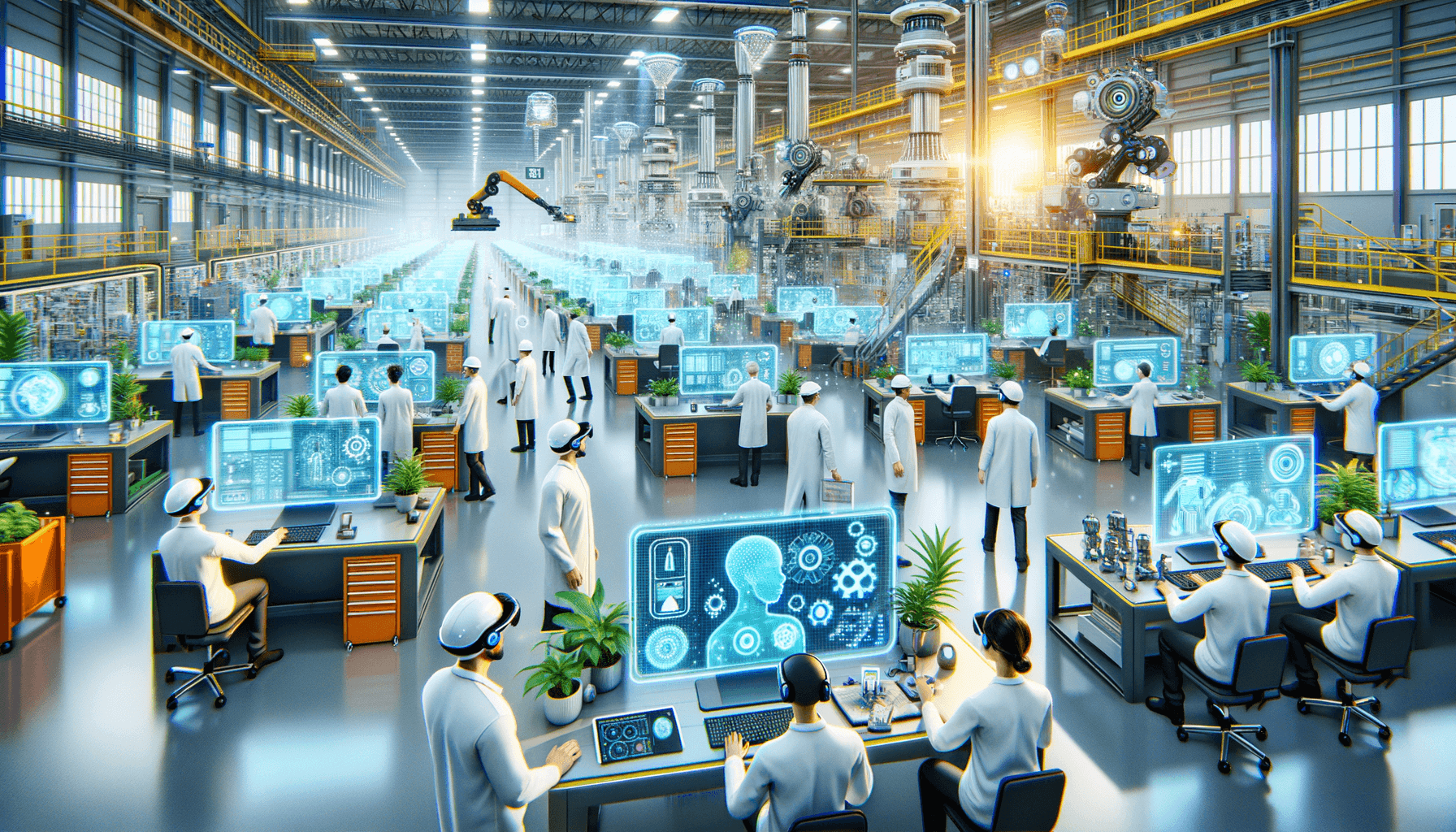

Imagine the year 2030, where manufacturing is redefined by the striking advancements in Augmented Reality (AR) and Virtual Reality (VR). As the sector journeys towards a towering market value of $7.6 billion, innovators like Siemens and Ford are already setting the pace, using these technologies to refine design and ergonomic assessments.

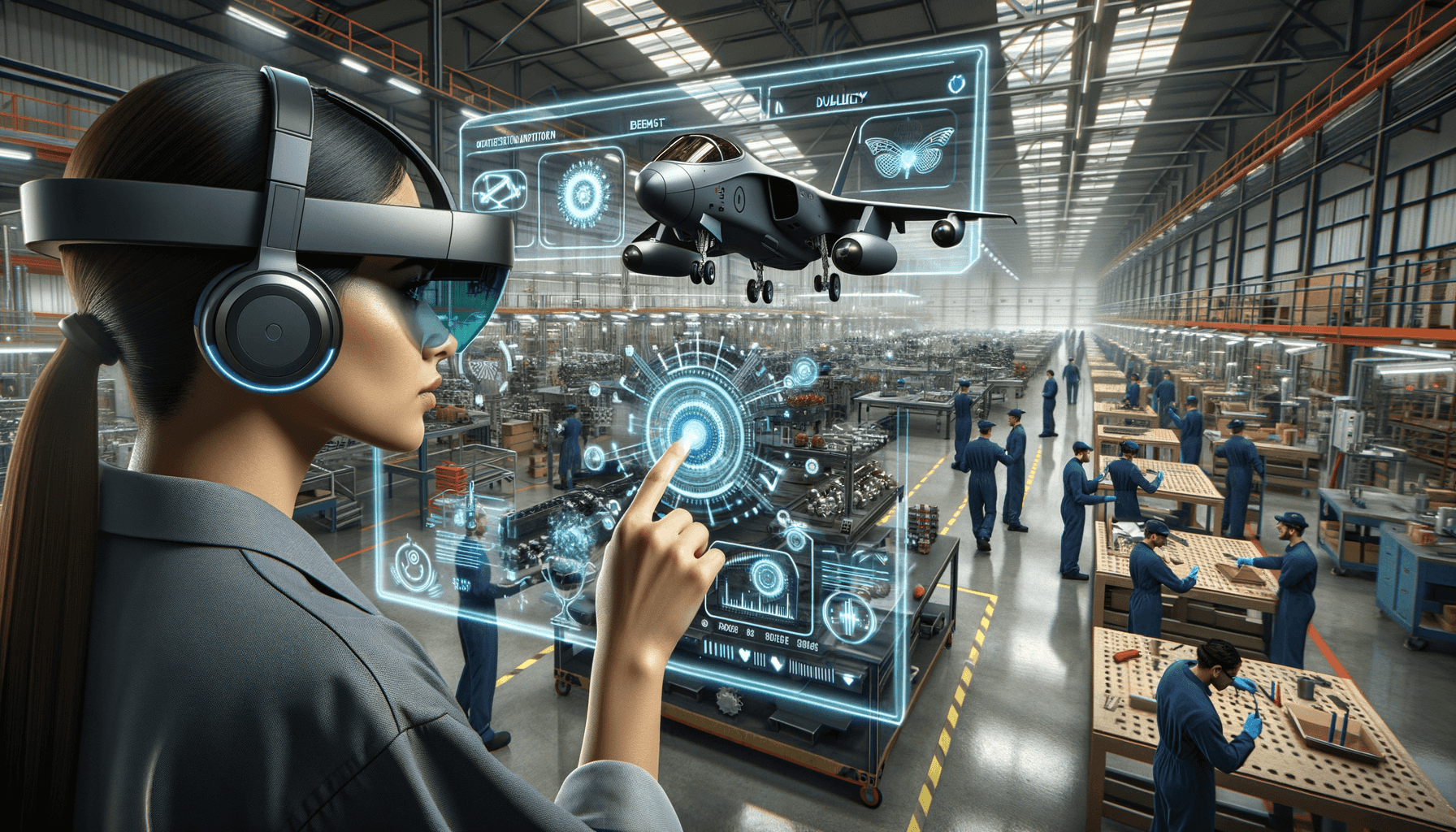

But what’s next? Statista projects a whopping $19.8 billion investment in AR/VR for manufacturing. The future is vibrant with AI-driven maintenance, holographic teamwork, and personalized production experiences. In this realm, heavyweights such as Microsoft, Google, and PTC are steering the ship, crafting tools that pivot the industry toward unprecedented efficiency and sustainability.

As the oldest AR company in the U.S., Gravity Jack leads this thrilling odyssey, offering a partnership to navigate these transformative tides. Delve into our full article to glimpse the fascinating evolution of AR and VR in manufacturing and see how we can embellish your enterprise with these cutting-edge technologies.