Augmented Reality: Revolutionizing Training in the Manufacturing Industry

Introduction

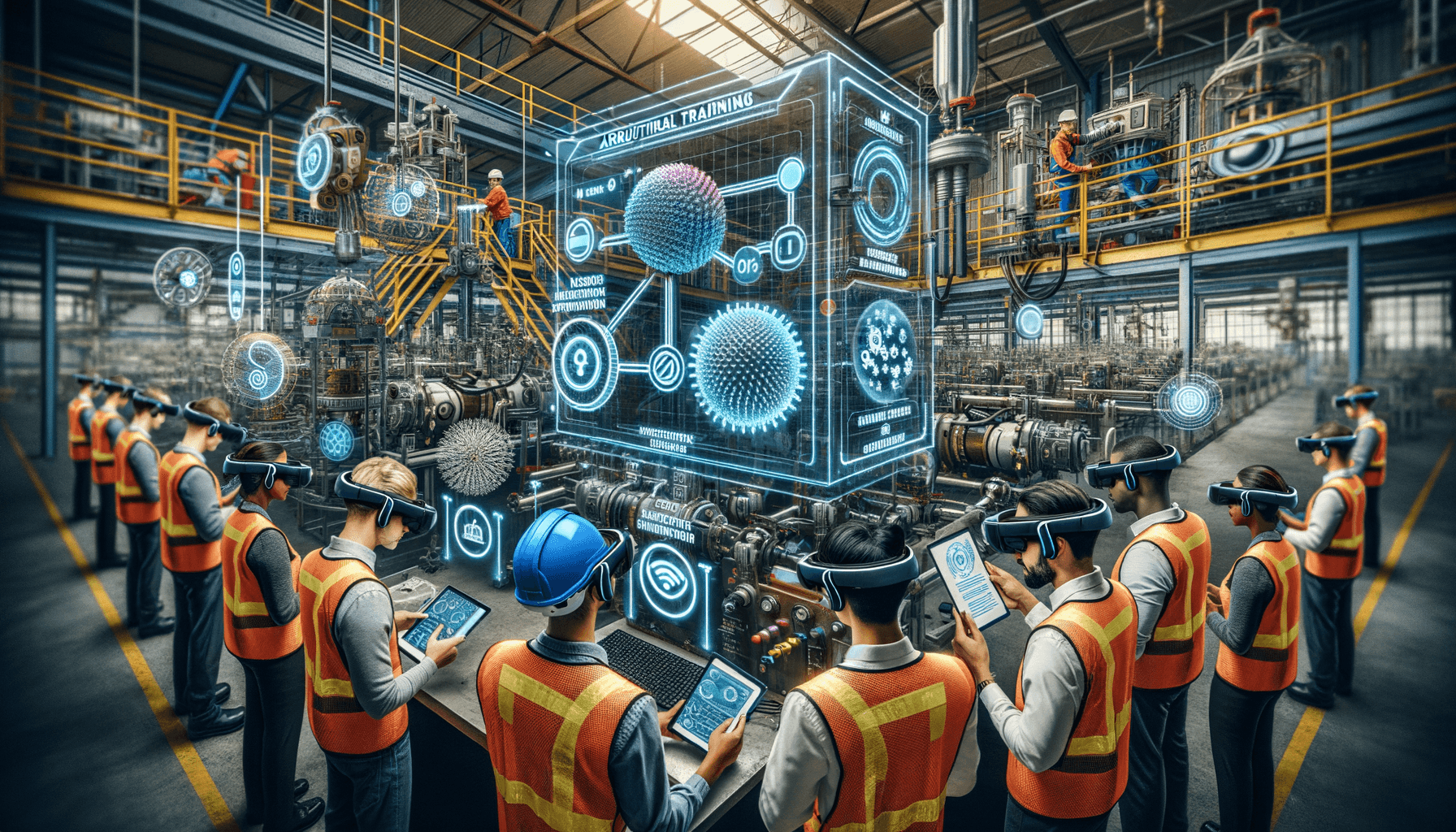

Augmented Reality (AR) is not just a novelty; it’s rapidly becoming a cornerstone in the evolution of training within the manufacturing sector. As the world’s industries stride towards innovation, AR emerges as a transformative tool in redefining traditional practices, from intricate assembly line processes to handling complex equipment. The potential of AR in enhancing operational efficiency and precision is becoming increasingly clear.

AR in Manufacturing: A Technological Leap Forward

In the labyrinth of manufacturing, precision and efficiency are the twin pillars of productivity. Augmented Reality ushers in an era where these attributes are significantly attainable. A staggering forecast by PwC anticipates that AR and VR will inject a colossal $1.5 trillion into the global economy by 2030. AR has the lion’s share of this growth, promising to account for 68%.

Reducing Errors and Amplifying Productivity

The numbers speak volumes—with the adoption of AR training solutions, error rates plummet by an astounding 94%, while productivity surges by 30%, according to PwC. By simplifying complex processes and reducing the risk of mistakes, AR not only bolsters confidence among workers but also streamlines the path to excellence.

Market Expansion and Sector-Wide Acceptance

The global AR market is on a trajectory to reach approximately $72.7 billion by 2024. This is fueled by a broadening recognition of its benefits in enhancing productivity, shrinking costs, and refining training methodologies across various industries.

Case in Point: Industry Titans and AR Integration

In the vanguard of embracing AR for workforce development are blue-chip leaders like Siemens and Boeing. Siemens employs AR for intricate training on gas-turbine assembly—introducing clarity and interactivity to complex tasks. Boeing, on the other hand, arms their technicians with AR to skillfully navigate the assembly of wiring harnesses.

Spotlight on Manufacturing Success Stories

- Porsche: The “Tech Live Look” initiative stands out as an example of AR’s practical application in manufacturing. This ingenious AR eyewear aids mechanics with on-the-spot expert guidance, ensuring accuracy and expediency during repairs.

- Caterpillar: This heavy equipment giant integrates AR into their training programs, equipping employees with immersive simulations that mirror real-life machine operation scenarios.

Gravity Jack: Pioneering Tailored AR Training Solutions

Among the frontrunners in crafting impactful AR experiences is Gravity Jack. With a focus on client-centric customization, our AR Training Solutions cater specifically to the nuanced requirements of expansive manufacturing companies.

Case Study Highlight: A prime illustration of our prowess is the work executed for L’Oréal. By integrating augmented eyewear, L’Oréal’s operators receive real-time, hands-free instructions, all while maintaining unwavering attention on their tasks.

Why Choose Gravity Jack?

With Gravity Jack, you gain a partner uniquely qualified to:

- Create customized AR training solutions tailored to your enterprise’s specific requirements.

- Utilize AR to decrease training errors, enhance learning retention, and support complex task mastery.

- Leverage a wealth of industry experience, technical expertise, and a deep understanding of the manufacturing landscape.

Conclusion and Call to Action

The inexorable march towards digital modernization in manufacturing is palpable. The cultivation of AR technology within this domain is set to advance, offering businesses the opportunity to elevate their operational capabilities and foster unparalleled training experiences.

As pioneers in the field of AR, Gravity Jack stands ready to guide large manufacturing enterprises through their digital transformation journey. We invite you to explore the boundless possibilities of AR with us, sharpening your competitive edge in a rapidly evolving market.

Should you seek to explore what AR can do for your manufacturing training initiatives, kindly consider reaching out to our team at Gravity Jack. Dive into the future of manufacturing with AR training solutions that are not only state-of-the-art but also sculpted to fit your company’s exact needs.