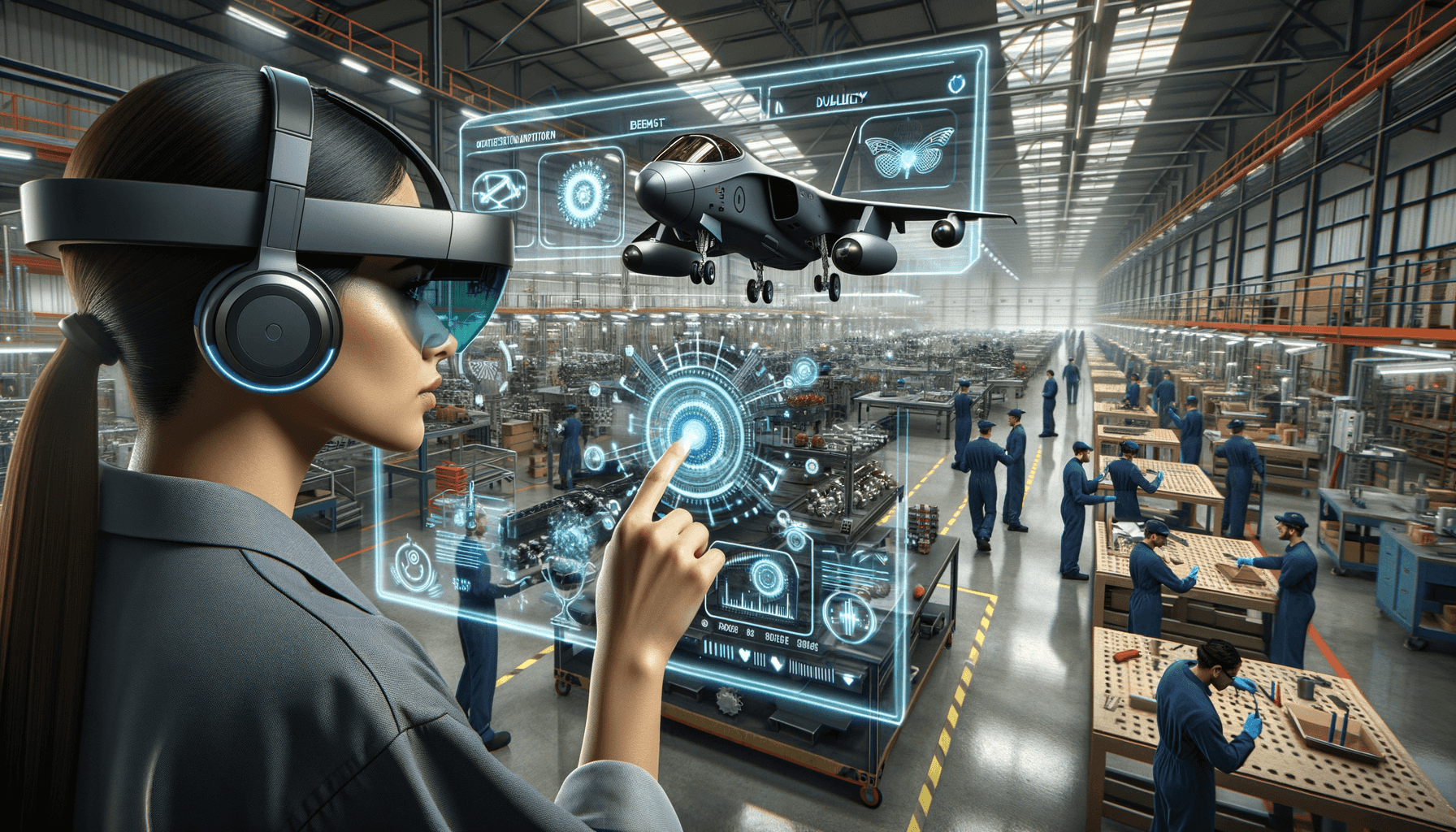

Explore the Transformative Role of Augmented Reality (AR) in Manufacturing Quality Control

Augmented Reality: The Game-Changer in Manufacturing Inspection and Quality Control

The manufacturing industry has entered a new era of innovation with the integration of Augmented Reality (AR) into quality control and inspection processes. As a globally recognized pioneer in Augmented Reality solutions, we at Gravity Jack are at the forefront of this technological revolution, offering sophisticated AR tools that are reshaping how manufacturers enforce precision and excellence.

The Impact of AR on Quality Control and Inspection

Streamlining Inspection Tasks:

AR-powered visual overlays simplify the interpretation of complex data, allowing inspectors to perceive and understand intricate details with unparalleled clarity. This visual assistance is vital for ensuring high-standard quality checks and minimizing human errors during the inspection phase.

Enhancing Real-time Fault Detection:

Immediate data analysis and defect detection are crucial in preventing costly production delays. Our AR solutions offer real-time insights that can pinpoint discrepancies and potential issues on the spot. This prompt intervention saves time, reduces the waste of resources, and mitigates the risk of substantial financial loss.

Assuring Product Integrity:

Detecting defects early in the manufacturing timeline is key to maintaining product integrity. With Gravity Jack’s AR technology, potential flaws can be identified and addressed at any stage, resulting in products that consistently meet and exceed industry standards.

Gravity Jack’s Role in Elevating Manufacturing Standards

At Gravity Jack, we have developed bespoke AR solutions that integrate seamlessly into existing quality assurance protocols. Our innovative tools are not only designed to enhance efficiency but also to drive excellence in manufacturing standards. We empower our clients with technology that offers:

- Real-time collaboration between technicians and specialists

- Interactive training modules for staff to quickly grasp complex concepts

- Sophisticated analytics to monitor and refine processes continually

Examples of Excellence: AR in Action

Notable industry giants have already harnessed the potential of AR in their quality control operations:

-

Boeing streamlined aircraft production by implementing AR to assist with wiring configurations, achieving a remarkable 25% reduction in production time.

-

Porsche leveraged AR glasses to connect their technicians with remote experts, significantly expediting service resolutions.

-

Unilever embraced AR to train employees in quality inspection, enhancing both accuracy and efficiency in their operations.

The Future of AR in Manufacturing

The trajectory of AR in manufacturing points towards a future where precision, speed, and quality are paramount. The growth of the AR market in manufacturing, with a projected CAGR of 21.3% leading up to 2025, underscores the technology’s critical role in shaping the industry’s future.

Partnering with Gravity Jack: Your Competitive Advantage

Embrace Innovation:

By choosing Gravity Jack’s AR solutions, manufacturers can secure a significant advantage in a competitive market. Our commitment to continuous innovation ensures that our clients are equipped with the most advanced AR tools available.

Optimize Your Operations:

Our AR solutions are meticulously tailored to align with your operational needs and are built to catalyze your journey towards operational excellence.

Drive Efficiency and Integrity:

Through the strategic implementation of AR, we help our clients streamline quality assurance processes, boost efficiency, and reinforce the integrity of their products.

We invite you to experience firsthand how Gravity Jack’s AR technology can transform your manufacturing quality control and inspection procedures. Connect with us to discover the potential of AR and elevate your manufacturing standards.

Contact Gravity Jack Today to learn more about our innovative AR solutions tailored for manufacturing excellence.