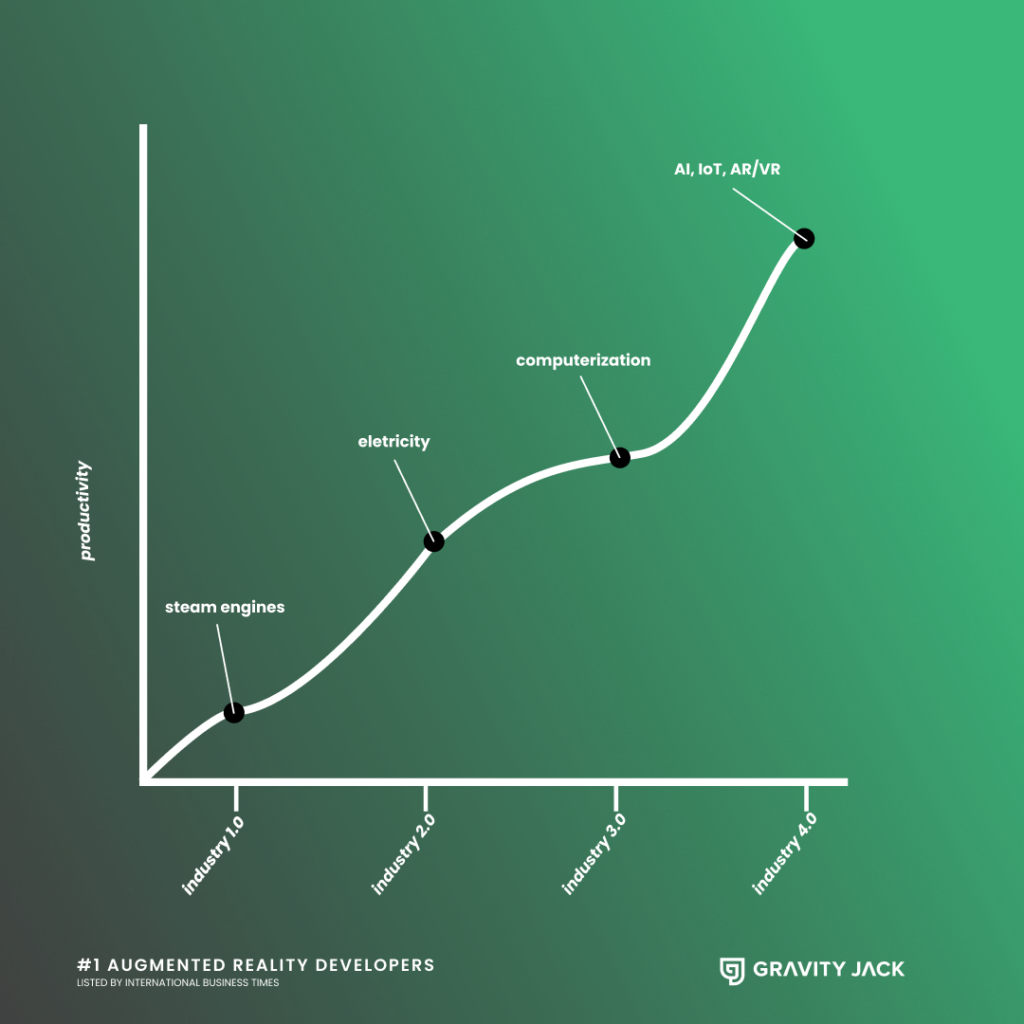

A paradigm shift in manufacturing is underway and has been coined, “Industry 4.0”. Also known as the fourth industrial revolution, Industry 4.0 is a movement driven by advanced technologies and digital transformation. It includes the integration of several key technologies like the Internet of Things (IoT), cloud computing, and artificial intelligence (AI). Not surprisingly, augmented reality (AR) is proving to be a key player in Industry 4.0.

Gone are the days of squinting at manuals or flipping through thick binders for guidance. It’s like trying to find a needle in a haystack, except the haystack is on fire and the needle is crucial information buried in Appendix Z, Section 17, Subsection C, Paragraph 42. Not only does AR optimize these efficiency bottlenecks, but it also removes critical safety hazards along the way. Here’s how.

How Augmented Reality Transforms the Manufacturing Landscape

Augmented reality is more than a buzzword; it’s a tool capable of redefining the way we see and interact with the world around us. And nowhere is this transformation more profound than in the manufacturing industry. With AR, crucial information is no longer confined to the pages of a manual or buried in the depths of a database. It’s right there in front of you, floating in the air like a digital angel — ready to provide real-time analytics, maintenance schedules, and troubleshooting guides.

Thanks to devices like the HoloLens and Apple Vision Pro, this can all take place in a hands-free environment. Need to understand how a new piece of equipment operates? Just point your AR device at it, and voila! Step-by-step instructions appear before your eyes, guiding you through the process with ease.

Enhancing Collaboration and Safety Training

AR isn’t just about making individual tasks easier; it’s also a game-changer when it comes to collaboration and training. Even with your team stationed across the globe, working on a complex project is now a possibility with AR-powered remote assistance. Teams can now bring everyone together virtually, overlaying instructions and annotations onto the real world in real-time. It’s like hosting a high-tech team-building retreat without the awkward trust falls.

According to a study by PwC, 35% of manufacturing executives believe that AR will be most beneficial in improving workplace safety. With AR-enabled safety features, such as real-time hazard detection and virtual training simulations, workers can navigate potentially dangerous situations with confidence and clarity. With AR training simulations, workplace newbies can dive into lifelike scenarios without the risk of breaking expensive equipment or causing catastrophic meltdowns. AR provides an environment where employees can learn by doing, minus the sweaty palms and nervous glances from the boss.

AR’s Role in Industry 4.0

A large component of Industry 4.0 in manufacturing will be the development of smart factories, where every machine, and every process, is interconnected and optimized for peak performance. And guess who’s leading the charge? You guessed it—AR. Augmented reality will literally be the backbone of these operations. Imagine machines equipped with AR sensors, detecting anomalies before they become disasters, or predictive maintenance alerts popping up right when you need them. AR is literally like having a portal into a factory’s future capable of predicting machine malfunctions. The best part is you don’t have to get into a Delorean with Doc Brown to see into the future.

How AR Streamlines Manufacturing Processes

In the fast-paced world of manufacturing, every second counts. That’s where augmented reality swoops in to save the day, supercharging efficiency and turbocharging production processes.

According to research by ABI, AR in manufacturing is expected to generate $7 billion in revenue by 2022, thanks to its ability to streamline operations and boost productivity. With AR-enabled workflows, workers can access critical information and instructions without interrupting their tasks, eliminating downtime and maximizing output.

Technicians can now perform routine maintenance on a piece of equipment, while AR overlays provide real-time guidance and troubleshooting tips, speeding up the process and minimizing errors. With AR, tasks that once took hours can now be completed in a fraction of the time, freeing up valuable resources for other projects. Additionally, AR-powered inventory management systems can optimize supply chains, reducing waste and ensuring that materials are always available when needed. By digitizing and automating manual processes, AR is transforming manufacturing into a well-oiled machine (manufacturing pun intended) of productivity and precision.

Augmented reality isn’t just a fleeting trend. It hasn’t even begun to reach its full potential or adaptation and will ultimately prove to be the cornerstone of a new era of manufacturing innovation. As technology continues to evolve and AR becomes more accessible, we can expect to see an explosion of creativity and efficiency on the factory floor.

In Conclusion

In Industry 4.0, augmented reality will seamlessly intersect the physical and digital worlds, ushering in an era of unprecedented collaboration, productivity, and safety. With AR as the guide, manufacturing companies will navigate the ever-changing landscape of industry with confidence and clarity, unlocking new possibilities and propelling us toward a future limited only by our imagination. Many have already embraced the ARvolution. Is your company ready for what the future holds? Because the outlook for manufacturing in Industry 4.0 has never looked brighter.