Augmented Reality: The New Frontier in Plant Worker Training and Productivity

Enhancing Efficiency on the Shop Floor

The industrial landscape is undergoing a significant transformation, propelled by the innovations in Augmented Reality (AR). With a market poised to expand from $17.67 billion in 2020 to a staggering $340.16 billion by 2028, AR is not only a trend but a revolutionary tool for enhancing plant worker productivity—Gravity Jack is at the forefront of this revolution.

Elevating Operations with AR

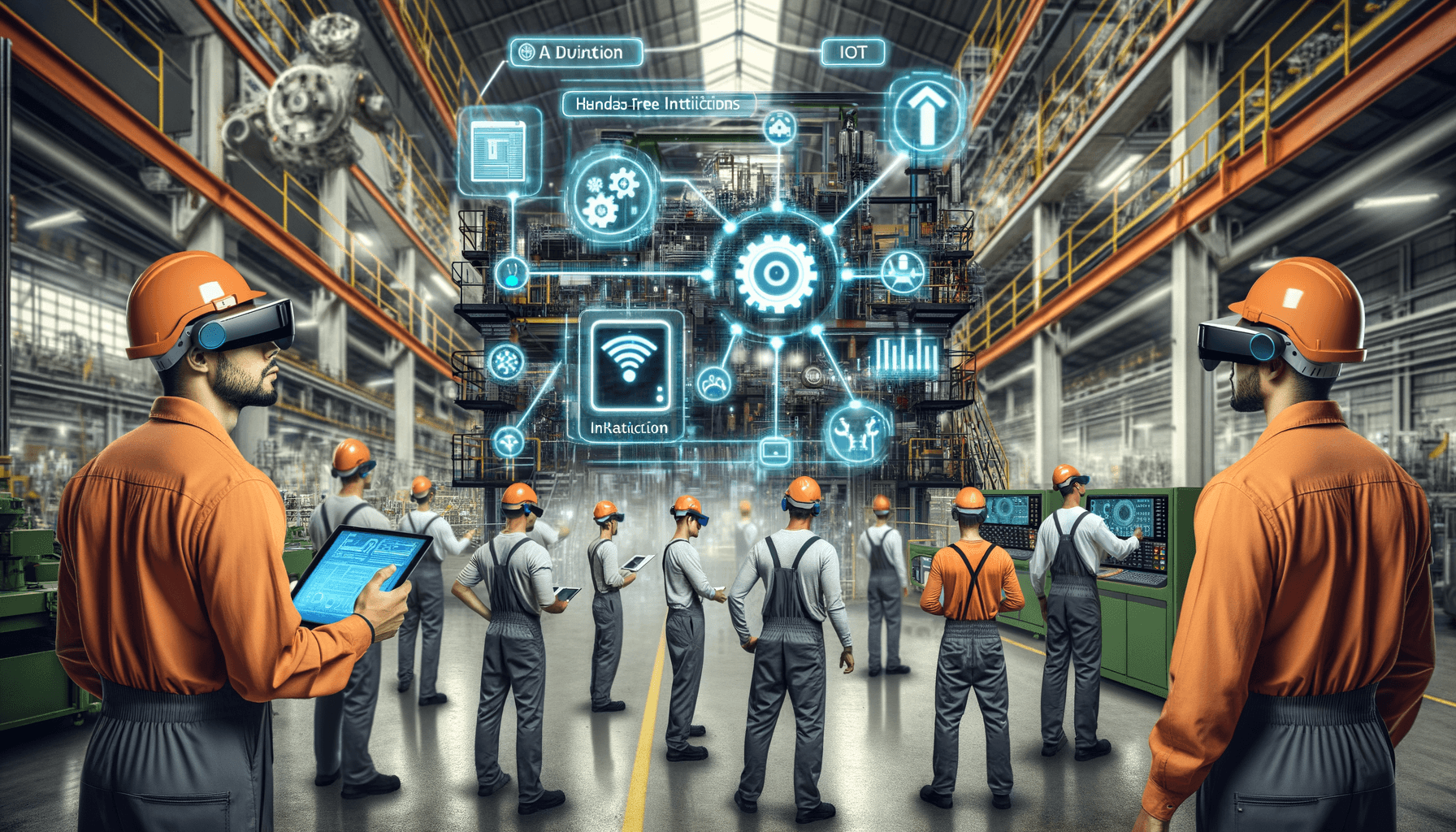

AR applications are not just futuristic concepts; they are current realities improving equipment maintenance, operations, and collaborative work within plant environments:

- Direct Instructions with AR: Plant workers receive real-time, overlaid instructions on machinery, providing an interactive guide and reducing the time required for referencing manuals or seeking expert assistance.

- Real-Time Data through IoT Integration: Combining AR with IoT allows workers to visualize sensor data instantaneously, preempting potential malfunctions and optimizing equipment performance.

- Hands-Free Workflow Support: By using AR headsets, workers can engage in complex, hands-on tasks without losing sight of necessary digital guidelines, making processes more efficient and safer.

Case Studies Confirming AR’s Impact

Illustrative success stories include:

- Boeing: Achieved a 25% improvement in wiring harness installation by integrating AR glasses into their processes.

- DHL: Not only reduced picking errors by 25% but also increased productivity by 15% through the use of AR-powered glasses.

ROI: Investing in AR Training Yields Long-Term Benefits

Investments in AR training solutions stand to significantly improve worker efficiency—up to 30%—while also reducing errors by 25%. The long-term return on investment is clear: enhanced productivity, minimized downtime, and streamlined workflows.

Gravity Jack’s AR Training Expertise for the Construction and Plant Industry

At Gravity Jack, we specialize in developing customizable AR training solutions specifically tailored for the construction and plant industry:

- Our tailored solutions significantly reduce training time.

- Workers can avoid potential safety hazards through more engaged learning.

- Our immersive AR experiences help solidify learning, enhancing knowledge retention.

- The result is a clear growth in productivity and operational accuracy.

With a deep commitment to innovation and quality, Gravity Jack has established a reputation as a leader in AR development, offering solutions that are not only effective but also adaptable to the unique needs of each client.

Major players in the industry, including names like General Electric, Lockheed Martin, and Siemens, have already begun leveraging AR solutions for enhancing their workforce’s capabilities, hinting at the widespread recognition of AR’s value proposition.

Conclusion: Embracing AR for Future-ready Training and Productivity

The implementation of Augmented Reality in the training of plant workers heralds a new era of industrial efficiency and effectiveness. As market adoption continues to surge, the promise of AR in transforming the plant and construction sector’s productivity becomes increasingly tangible.

If you are looking to equip your workforce with cutting-edge AR training solutions and drive sustainable productivity growth, consider partnering with Gravity Jack. Our experience, expertise, and commitment to excellence ensure that your investment in AR will not only meet but exceed expectations.

To explore how our specialized AR training solutions can benefit your operations, reach out to us at Gravity Jack: We are ready to support your journey toward enhanced productivity through innovative technology.